Posted by Rachel Westall on 21 April 2020

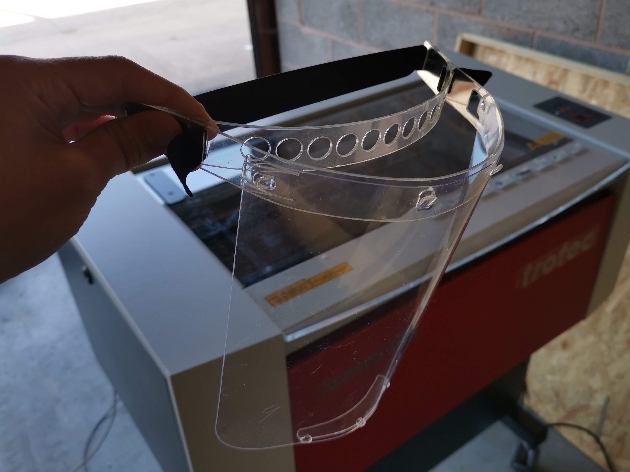

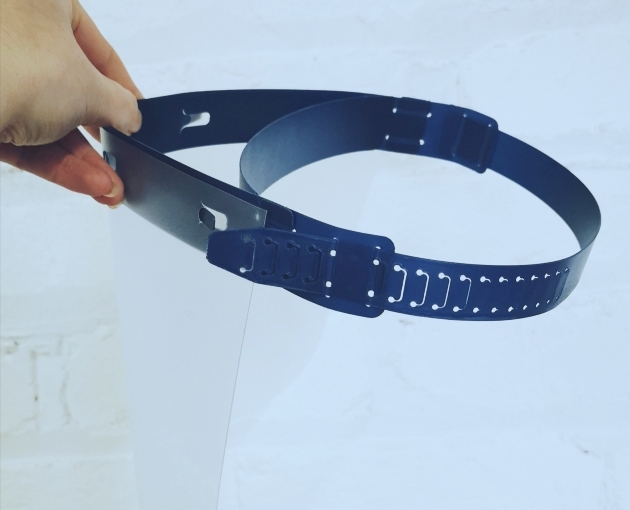

The most common materials used in the production of PPE are clear acrylics and plastics such as PET which are laser cut and then manually assembled. By laser cutting these materials, face shields, visors and surrounds for shop counters can be quickly and easily produced to meet the guidelines laid out by the UK government. Trotec, a market-leading supplier of laser cutting, engraving and marking machines has created a design file for face shields to help businesses looking to contribute PPE to the frontlines, allowing the whole piece to be cut from a single sheet of material, effortlessly optimising production.

It's not just the types of businesses you might expect who have switched their focus in support of PPE production. Companies from a wide range of industries including acrylic fabrication, personalised gifts, universities, schools and even paper processing firms have stepped up to offer their support to the fight against Covid-19 using their laser cutters. This has been possible due to the versatility that the laser cutter provides, it's very easy to switch production to a new material, even if it has never been used on the machine before.

Trotec customer, Patternise, are more familiar with creating beautifully intricate laser cut paper displays which are often used for events and high street shop windows. Rob Payne, business owner said: "We immediately accepted the challenge to make visors for key frontline health workers, primarily manufacturing on our high-speed Trotec GS1000 laser cutting machine. We were able to supply 1600 visors within an extremely aggressive timeframe, and thanks to the support of our suppliers, we were able to supply all visors at no charge to those in desperate need."

The worldwide laser community has also been quick to share artwork files and advice to enable even small craft businesses to easily switch their production to make PPE.

Elise Williams runs Etsy shop, Goozeberry Hill, specialising in personalised gifts products which are predominantly made from wood, paper and card. Elise had never cut plastics on her Speedy 300 laser cutter before, she said: "There was a lot of trial and error before I perfected the cutting, but now I am full steam ahead with over 750 masks (and counting!) being distributed in my area. They have gone to bus drivers, care workers, mental health nurses and everyone in between. The project has been funded by generous donations from the public."

Although there are several different technologies available, laser cutting is proving to be the production method of choice for many organisations. The Engine House in Bexley provides an innovative workspace and incubator for start-ups as well as a Tech Makers studio for rapid prototyping.

Having been contacted by the local authority, The Engine House team jumped into action. Initially using traditional methods such as injection moulding and die-cutting, the team decided to make the switch over to their laser cutter having waited a week to receive their initial design from the fabricators, only to find it needed some changes - The process was too slow.

Head of creative services at The Engine House, Lewie Winters said: "We needed proof of concept for our newly designed face shield and decided to put our laser cutter to use. PETG was the material of choice so we got some on order which was going to arrive in 24 hours, we then used a mixture of card and laminate paper to prototype the design on our laser cutter which was a success.

"Within a matter of hours we were able to take an idea and turn it into reality, we are now likely to obtain CE certification this week and will be able to produce 20,000 units per day to help supply the NHS."

Computer Engineer, Andrew Rudge, had been using a 3D printer with an output rate of one visor every two hours, he has since switched production to a Trotec Speedy 100 laser cutter which has drastically increased production capacity. Andrew said: "I've been able to make 70 visors in a few hours using the laser and now have 200 complete kits sent out directly from the Speedy 100, with another batch of 1000 underway."

Alongside PPE, many companies have been creating other solutions to help in the fight against Covid-19, including social distancing signage and acrylic door openers which reduce contact with potentially dirty surfaces. Others are getting involved with cutting fabrics used to produce medical 'scrubs'.

The ability to react quickly in a marketplace has been proven to support the longevity and ongoing success of many businesses. Although much of the activity which has been happening amid the Covid-19 pandemic has been not-for-profit, it has been evidence that in times of need, a laser cutter can be very quickly diverted to new tasks and materials. For Trotec customers, the free materials database provides guidance on machine settings to make it easy for customers to work with new substrates, while the online global community has seen Trotec users worldwide sharing ideas and supporting each other in the unprecedented circumstances that they are experiencing.

For more information visit www.troteclaser.co.uk